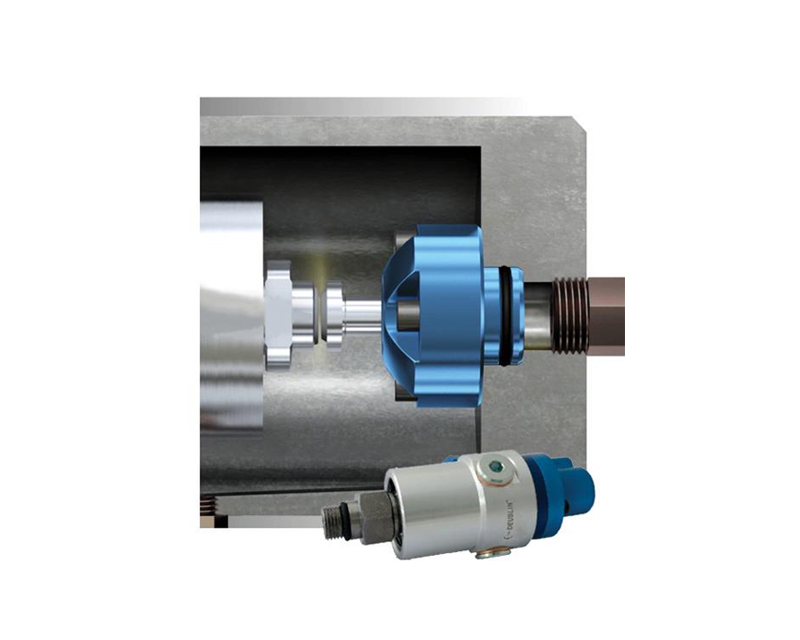

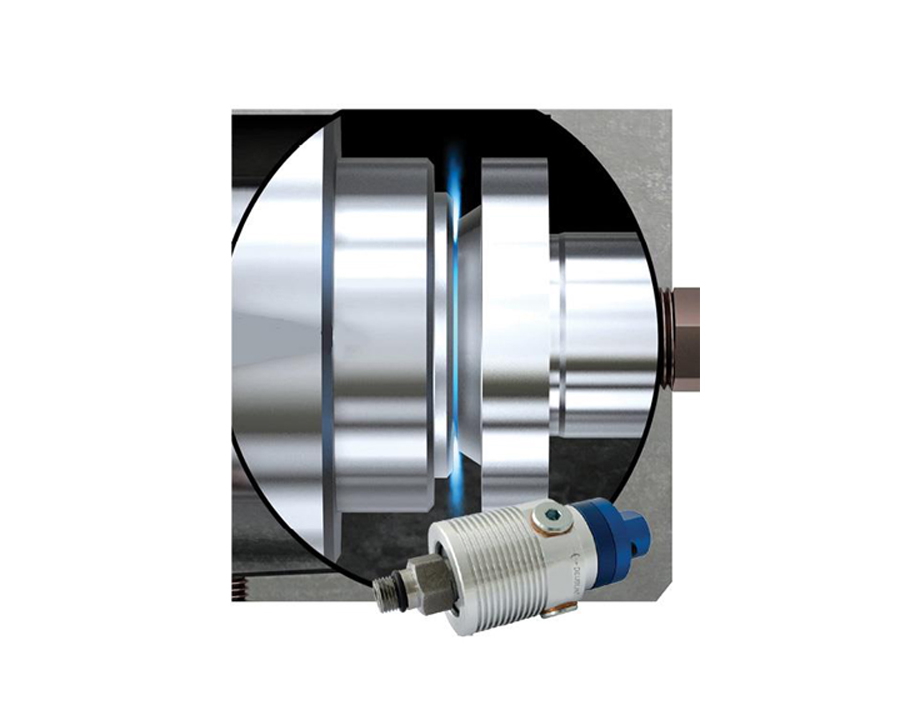

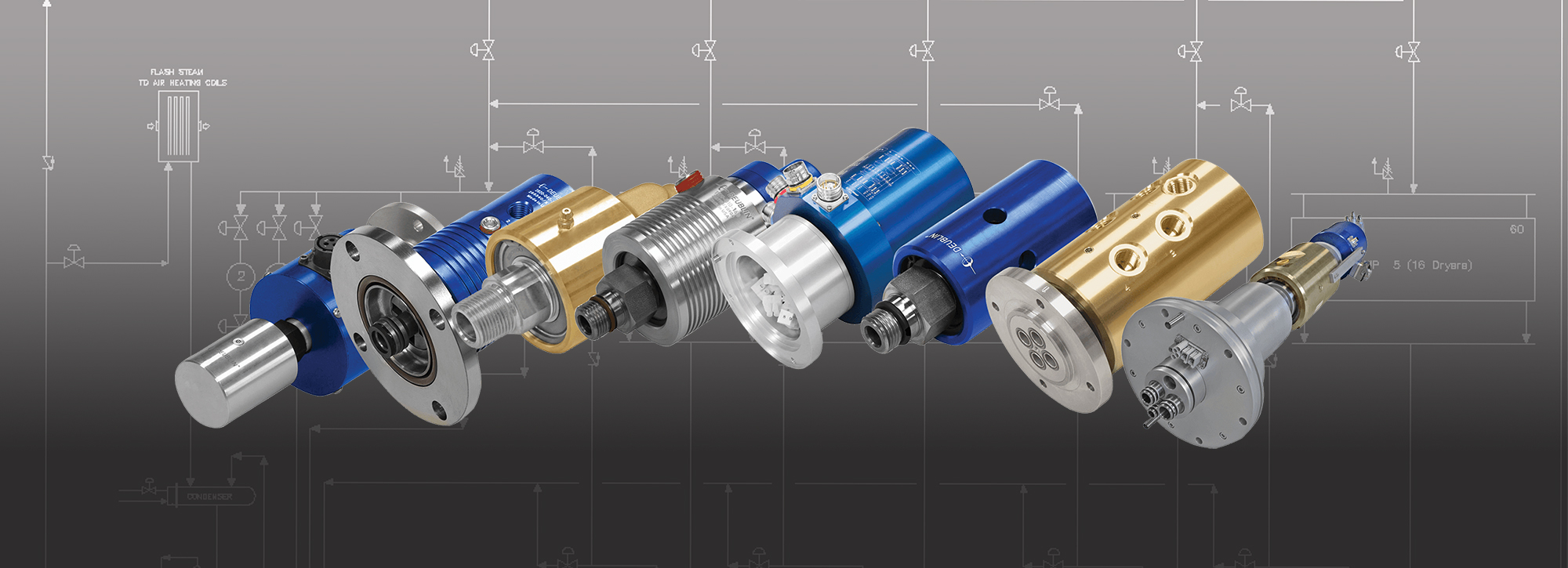

Engineered Solutions for Rotary Applications

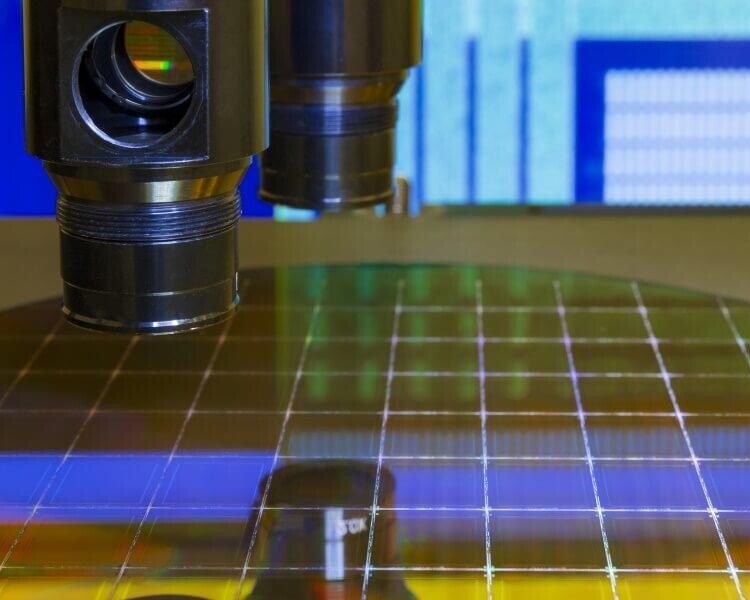

Industries

Deublin rotary unions and electrical slip rings are used by all kinds of industrial machinery and manufacturing processes.

How We Can Help

Grow your productivity with Deublin products, service kits, and technical support.

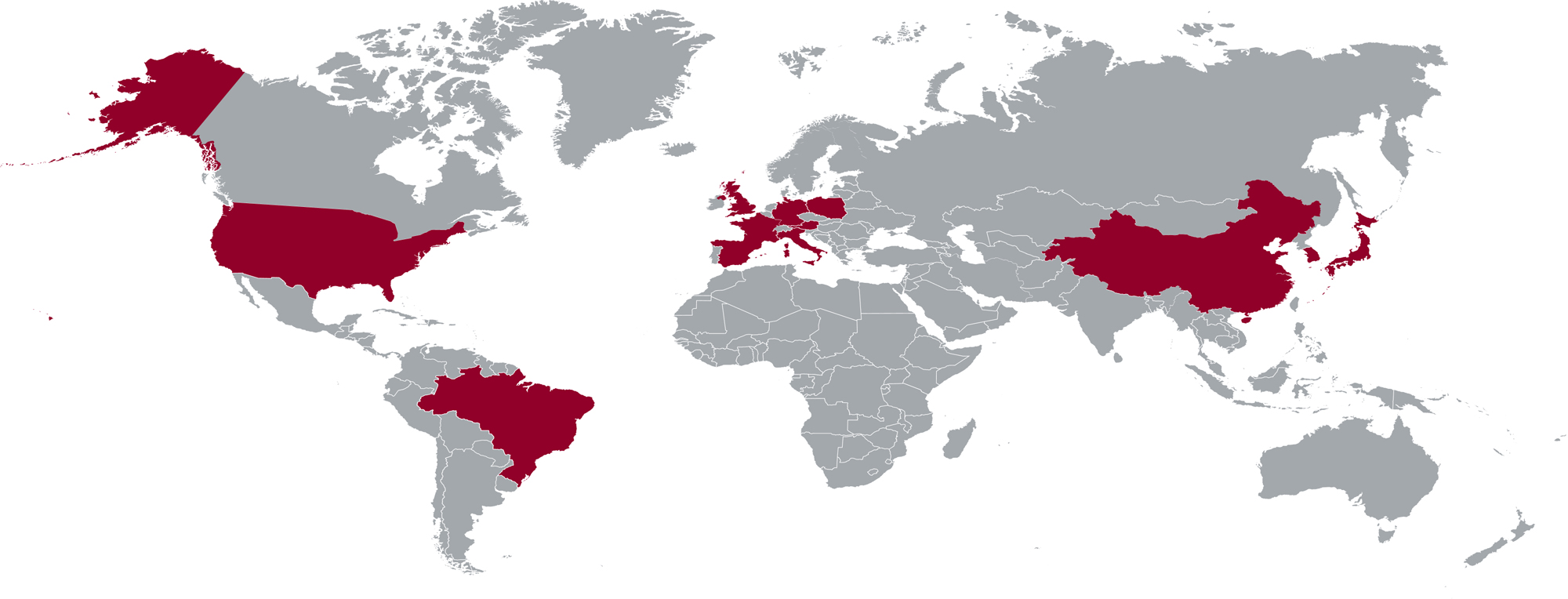

Worldwide locations

Regardless of your location, there is a Deublin office near you.